Pièces d'usinage CNC pour équipement d'automatisation

- SHD Precision Tech

- Shenzen

- 1 semaine

- 5000 pièces/mois

Livraison plus rapide

Finitions personnalisées

Tolérances dimensionnelles élevées

Capacités d'usinage complètes

Équipe expérimentée

Certificat ISO9001

Product Details:

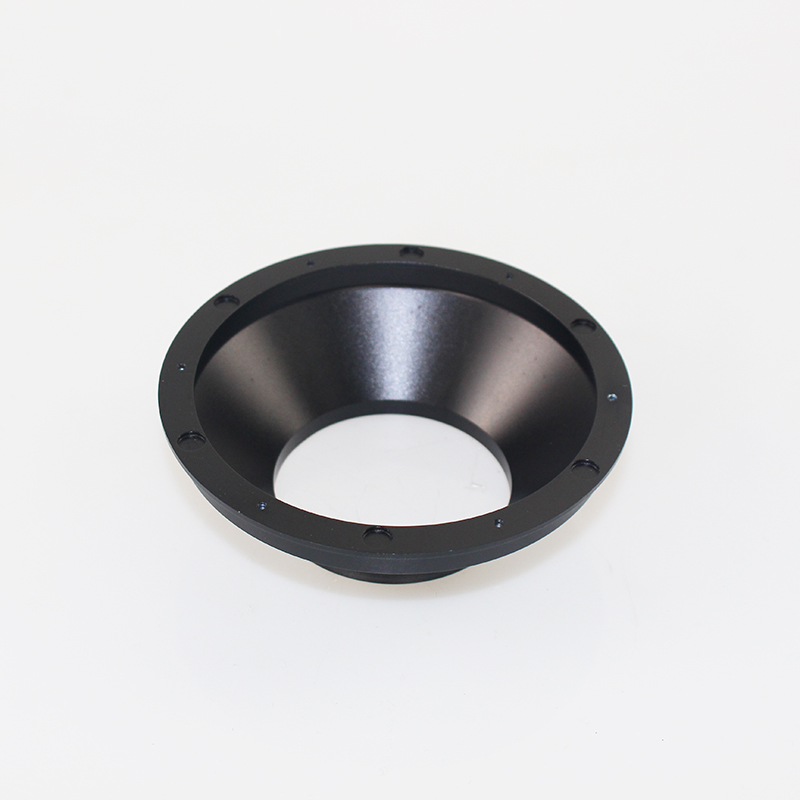

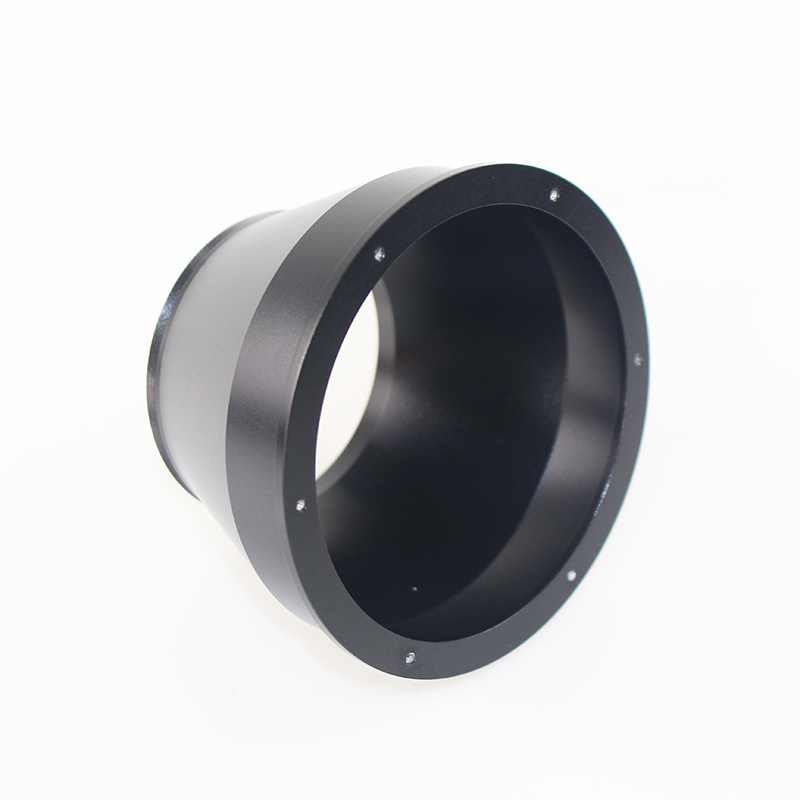

Service | CNC Machining Parts For Automation Equipment |

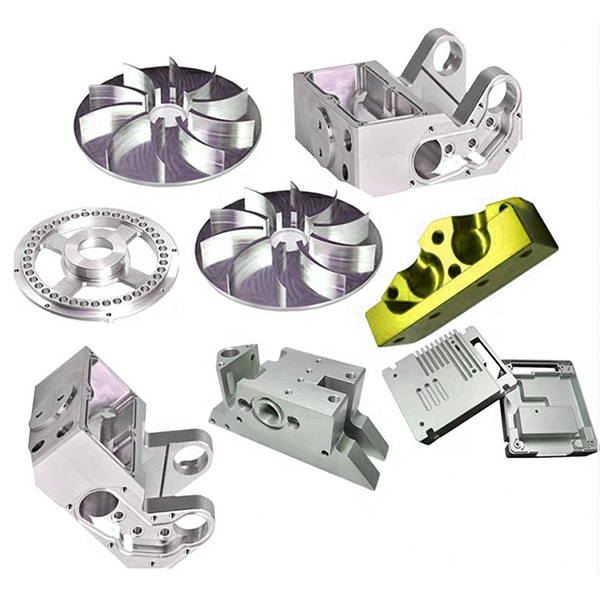

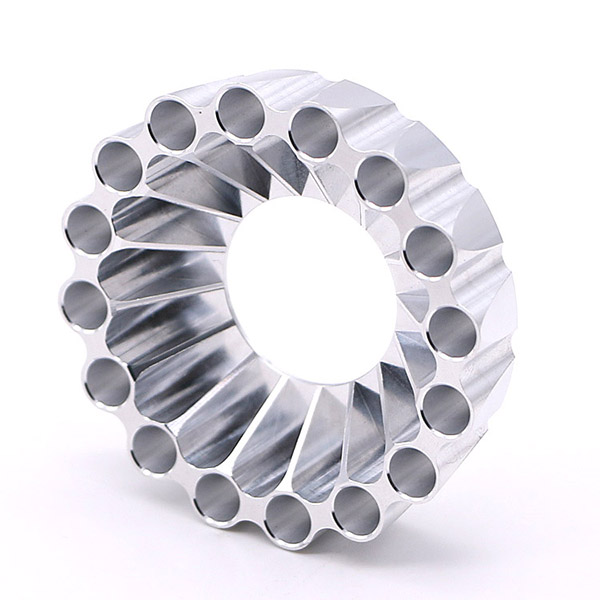

Available materials | Steel, Aluminum, Alloy, Brass, Copper, Bronze, Nylon, Acrylic etc. |

Process | CNC milling, turning, drilling, grinding, bending, stamping, and tapping |

Tolerance | 0.005mm~0.1mm |

Surface Roughness | Ra1.6-3.2 |

DRW format | PDF/DWG/IGS/STP etc. |

Equipment | CNC machining center, CNC turning, General milling machines etc. |

Capacity | 5,000 pieces per month |

MOQ | 1pcs |

Machining Scope | 1. Equipment/Machinery parts |

QC System | 100% inspection before shipment |

Payment term | T/T, Western Union, Pay Pal |

Surface treatment | Anodizing, zinc/chrome/nickel/silver/gold Plating, Polishing, Heat treatment etc. |

Shipment Terms | 1. 0-100kg: air freight priority 2. 3. As per customized specifications |

Packing | 1. Prevent from damage. |

Why Use CNC For Metal Machining?

High Accuracy and Repeatability

CNC metal machining allows a higher level of precision and accuracy. Production is completely automated by the program and the machining process is continuous. So every part or prototype will be replicated to the first one, making the manufacturing process fast and easy to give a completely consistent output.